This project was an exciting and rewarding process of designing a cargo bicycle in collaboration with Ugandan bicycle couriers.

The design was developed over a period of two years through a team of Ugandan advisors with myself. A prototype was created and brought to Uganda for three weeks. I met daily with the Ugandan couriers, tested the bicycle, and discussed revisions and improvements.

The project’s subject was the bicycle design, but the research objective was to learn what it means to design for the people of a very different culture and economic environment. Valuable lessons were learned regarding the design of products for people of developing nations.

The initial objective of this project was to design and develop a low cost utility bicycle with rural Ugandans as the target user. The solution could be appropriate throughout East Africa and other parts of the world with similar conditions. The design must be practical, manufacturable, unique and feasible. The bicycle must be able to carry loads up to 300 lbs in addition to the rider. It must withstand the rugged roads and conditions of the environment. It must be strong and durable, with minimal maintenance. And the most difficult constraint to meet is a retail target cost less than $80 USD.

In Uganda many residents use bicycles for transportation. Only the very prosperous can afford to buy and own a car or truck. Whether it’s to deliver some goods to the market, or to carry water from the well to their home, they rely on a traditional bicycle for their transportation needs. However, the bicycles that are available to them are unreliable, inefficient, heavy, incapable of carrying cargo, and of very poor quality.

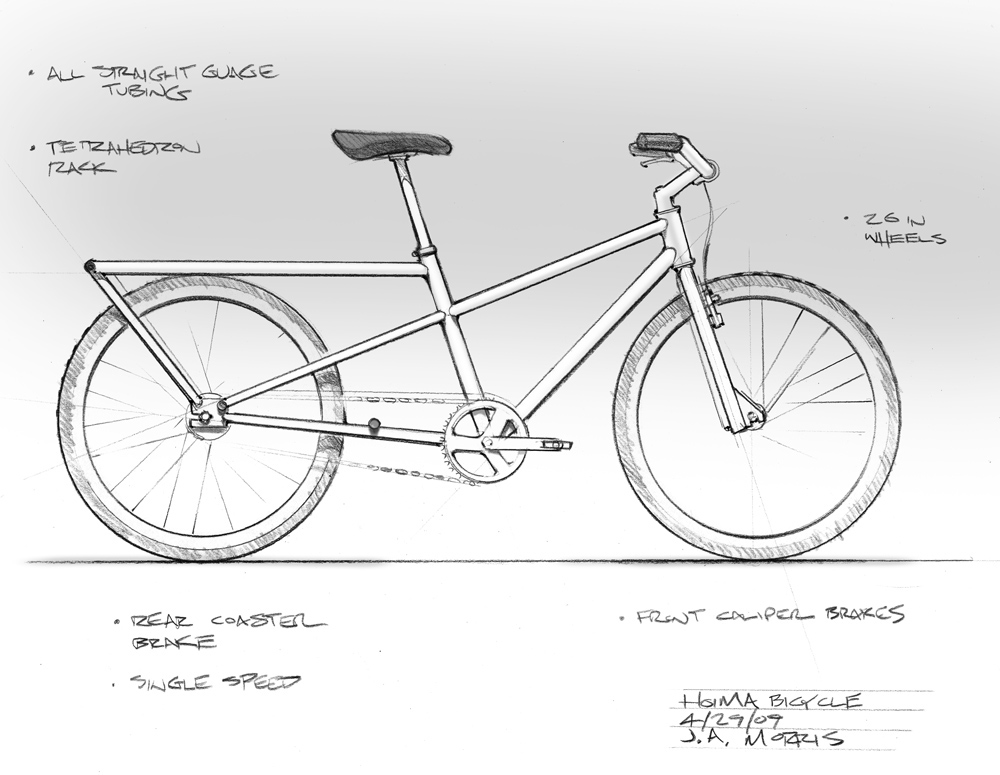

The first prototype design is essentially an elongated mountain bike with an integrated rack. The front geometry has comfortable mountain bike geometry with a low stand-over height, rigid fork, and 26 inch front wheel. The 20 inch rear wheel has been moved back, increasing its wheelbase 10 inches which allows for a more distributed load between the two wheels and provides more area for loads and passengers. A rear rack is designed to be integrated into the welded frame and is in the form of a tetrahedron, a very structurally rigid and lightweight form.

All extraneous parts and accessories were omitted. The rear wheel uses a coaster brake hub to eliminate rear cables, brake pads, and reduce maintenance. The drive train is a simple roller chain, single-speed freewheel and is geared low to roll at 12 mph at 90 rpm. (3.7 m (145 inches) per revolution development). A small rear wheel allows for a lower platform and center of gravity for carrying cargo. This would be advantageous for some types of low density cargo, such as firewood or charcoal and is stacked high on the bike. A small 20 inch wheel is structurally stronger but has higher rolling resistance than a 26 inch or larger wheel.

The design was revised to have two 26 inch wheels based on our user testing and feedback. The drawing above shows the revised design.